Logistics is the connection point between the supply chain and the consumer, the lead character of the Benetton Group business model. In this approach, that focuses on the person, the logistics strategy is based on customizing services based on the needs of the stores, reducing the environmental impact and achieving a higher level of garment traceability.

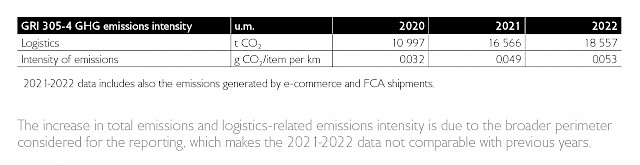

Emissions

Intermodal transportation

To reduce CO2 emissions related to logistics and distribution activities, intermodal transportation was also chosen in 2022 and in general the transportation modes with a least environmental impact such as rail transport (with a low polluting impact) compared to air transportation.

Saturation of transportation

Shipping at Benetton includes loading vehicles with loose packages and no use of pallets. This method optimises the loading space and truck saturation. The result is that one truck in five is eliminated from the road.

Deliveries

At the moment of the online purchase consumers can choose between home delivery or store pickup. Soon users will also be able to choose shipment time, selecting from urgent delivery by courier or standard delivery in 3-4 days, taking advantage of the Company’s logistics. The Group is also studying the possibility of delivering e-commerce orders to the final consumer by alternative, eco-friendly means - such as bicycles - in large cities like Milan and Rome.

Suppliers evaluation

As of the end of 2020, CSR issues and specific questions about the type of fleet have also been integrated as drivers for supplier selection, taking into account their environmental and social impact.