A commitment towards circular fashion

At Benetton we believe that shifting the apparel industry toward more circular solutions is a complex challenge with significant technical, economic, and business implications. Nevertheless, moving from a linear input-out model to a circular one, in which every element is regenerated and given a new lease of life, is a business imperative: we have a responsibility to protect the environment and reduce waste at every stage of our production process – from design, to sourcing, to manufacturing.

Design

Our designers and planners are trained on the principles of eco-design, with particular reference to:

• choice of inputs with sustainability criteria (raw materials from renewable sources and/or from recycling, reduction of the environmental impacts of processes, minimization of production waste);

• design of the life of the product, to favour its durability, limit the consumption generated by the garment during its use and contain negative environmental impacts (release of microplastics);

• end-of-life design of the product, favouring single material and identifying solutions to facilitate disassembly.

To the date, half of our garments are monofiber, therefore making recycling easier.

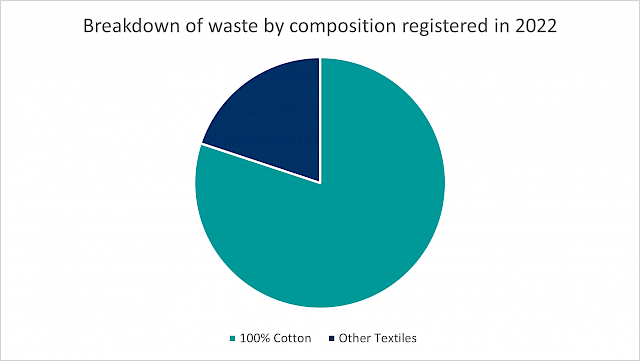

Scaling circularity

Benetton Group participates in the Circular Fashion Partnership, a project that supports the development of the textile recycling industry in Bangladesh, using waste from production processes to create new garments. The partnership facilitates commercial and circular collaborations between textile industries, fashion brands and recycling experts in Bangladesh, with the aim of generating economic value in the country by boosting the recycled fiber market. In 2022, three Benetton Group suppliers joined the project and, properly trained, began the collection of cotton production waste, which can then be sold and recycled. Benetton also intends to involve other suppliers in the CFP project, which represents an opportunity to scale the post-industrial recycling project.